|

StencilScan™ AOI Automated Stencil Inspection System |

|

WHAT IS StencilScan? StencilScan is a fully integrated (AOI), stand-alone inspection workstation for stencils, screens and boards after fabrication or after cleaning. StencilScan uses a PC Windows based software package integrated with a high-resolution, calibrated, A3 size flatbed scanner. This combination allows inspection of both stencils and screens for accuracy and blockage after cleaning, absence/presence/position/size of apertures and pre-inspect boards and stencils to Gerber data. CREATE STENCIL FABRICATION DATA StencilScan adds flexibility to the stencil and screen inspection process. Utilizing its calibrated scanner, StencilScan inputs stencils, screens, silver or diazo film, mylar images, technical drawings, actual PCBs or original hand-taped designs. With these inputs StencilScan is able to verify cut stencils/screens for accuracy, size and blockage, as well as producing necessary Gerber data for stencil/screen production. AUTOMATIC FEATURES Tired of using slow manual inspection methods? StencilScan offers various functions that quickly and automatically create necessary Gerber and verification data:

|

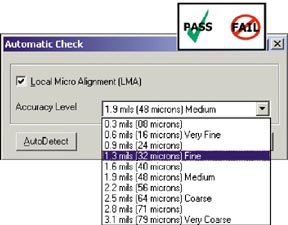

VERIFICATION Worried about the quality of stencils, screens or Gerber files? Use StencilScan's "check functions" to verify the accuracy of the data. The new LMA option allows for checking apertures as small as to 0.002" diameter (0.050 mm). These functions verify stencils and screens for production errors, accuracy, size, identify screen blockage, stretch or damage and step the operator automatically through all discrepancies of the verification results. PRODUCTION USES StencilScan creates Gerber files as well as other data used in stencil production, including: Silkscreens, Soldermasks, Padmasters, Stencil Files, Panelized Images, DXF and Gerber-274x files, etc. StencilScan permits fast and accurate comparison of stencils/screens to bare PCBs bringing automation and increased productivity to QC departments. WHY USE StencilScan?

|

|

100% Automatic inspection of stencils, screens and boards after fabrication or cleaning. Create Gerber files from boards, artwork or stencils. CAPABILITIES

|

|

|

SYSTEM FEATURES SCANNING

INSPECTION FUNCTIONS

AUTOMATIC FUNCTIONS

EDITING

OUTPUT

|

TECHNICAL SPECIFICATIONS SCANNER

*Reduced scanning area for 3200 & 4000 dpi COMPUTER*

*Recommended customer supplied minimum PC requirements. ADDITIONAL SYSTEM COMPONENTS

SOFTWARE OPTIONS

The following are trademarks of the indicated companies: Gerber, The Gerber Scientific Instrument Company; HP-GL, HP, Hewlett-Packard; Windows 95/98/NT 4.0/Me/2000, Microsoft®. Specifications subject to change without notice. |