MS2®

molten solder surfactant

(U.S. patent and foreign patent pending)

Unlike conventional

powders, oils, mechanical separators and even nitrogen

blankets, MS2® molten solder surfactant doesn't

just reduce solder dross in wave soldering machines—it

actually eliminates it.

By eliminating

dross, MS2® molten solder surfactant allows manufacturers

to reduce their solder usage by as much as 70%, depending

on production volume, resulting in significant cost

savings.

Dross is

formed when molten solder comes into contact with oxygen.

Dross consists of metal oxides plus otherwise good solder

metal that is bound up with the oxides and is thus unavailable

for soldering. This bound-up metal makes up as much

as 70% or more of the total amount of dross, which in

a typical wave solder machine can amount to as much

as 3 lbs. or more per hour.

Immediate ROI

|

- Reduces solder usage 40-75% based on production

volume

|

- Eliminates dross-related soldering defects

and rework

|

- Greatly reduces the cost of managing hazardous waste

|

MS2®

molten solder surfactant, which is available for both

leaded and lead-free processes, is a nontoxic, nonvolatile,

organic liquid that is poured onto the surface of the

solder bath.

About 200–300

ml is the average amount for an initial charge; a smaller

amount of fresh product is usually added once or twice

per shift.

MS2®

molten solder surfactant does not mix with the metal

but forms a thin floating layer that covers areas of

the solder surface excluding the wave, which it does

not disturb. There are no fumes or odor and no residue

is deposited on boards or components.

When MS2® molten solder surfactant is added to

the

solder bath, it prevents dross from forming on the surface,

and any dross generated by the exposed solder

wave is immediately converted back into usable metal,

so no dross accumulates.

Furthermore,

MS2® molten solder surfactant keeps on

removing metal oxides as solder is pumped through the

system, cleansing and purifying the bath. The result

is

lower surface tension; enhanced wetting and fewer solder-

related defects have also been observed.

As the layer

of MS2® molten solder surfactant continues

to convert dross back to metal, it will become thicker

and more viscous, and can be easily removed with a

supplied skimmer. The small volume of spent material

can then be inexpensively shipped back to P. Kay Metal

for recycling.

|

Q. How much MS2 can I expect to use?

A. While exact usage depends on machine configuration and time of use per day on average

you can assume that a machine generating between 2.5 and 3.0 Lbs of dross per hour will consume

1 liter of MS2 per 40 hours of operation. One liter will usually reduce 45 Kg or 100 Lbs

of dross back into useable solder.

Q. How does MS2 work?

A. the active ingredients in the MS2 complexes with metal oxides in the solder bath dross and

render them soluble in the bulk material. This material is also unique in its dual role as a heat

stable oxygen barrier and as an oxide scavenger. MS2 works with no discernible smoke or odor

if used within normal solder pot temperatures. Right out of the bottle MS2 is non-toxic and

non-irritating and the resulting spent organometallic waste presents no inhalation or contact

hazard.

Q. Does MS2 mix with the solder?

A. No. Not only do we know that because of the chemical formulation we have also confirmed

this through numerous independent lab tests. Lab test data is available from P. KAY Metal.

Q. Does MS2 normally contact the assembly being soldered?

A. No, MS2 does not mix with the solder or travel over the wave.

Q. How do I clean MS2 from a board or assembly if I mistakenly do so?

A. MS2 can be removed from circuit boards with a solution of hot water and 4% Environ Gold

816 saponifier.

Q. How do I clean MS2 from tools or machine components?

A. MS2 can be removed from machine components or tools by cleaning with a towel while the

item to be cleaned is still warm.

Q. Does MS2 corrode or have a detrimental effect on the materials that compose the solder

pot?

A. No

Q. Can MS2 be shipped by air?

A. Yes. There are no restrictions on shipping MS2 by any normal means.

Q. Is MS2 flammable?

A. No, MS2 is not flammable.

Q. Is MS2 conductive?

A. MS2 is not applied to the board and leaves no detrimental residue so this is not normally a

concern. Extensive SIR testing has been performed through independent labs. It is not conductive

in the fresh or unused condition. However, as it becomes spent it contains metal oxides

and possibility flux residues that can be conductive. Of course, dross is also conductive.

Q. What are the equipment manufacturer positions on MS2?

A. Most have no position just as they have no position regarding the brand of solder used. We

have had a comment that Our machine does not generate dross so why would the customer use

MS2? If everyone used MS2 than our dross free machine would loose its advantage. Frankly

we are still looking for that dross free wave solder machine.

Q. How should the small amount of MS2 be handled?

A. While the amount of spent MS2 will equate to a tiny fraction of the dross that would have

been generated there will be a few hundred milliliters per day of spent MS2 depending on production

volumes. The spent MS2 should be returned to P. KAY Metal or our distributors for

return to an authorized recycling center.

Q. Is there any special labeling for spent MS2?

A. Spent MS2 contains oxides of the metals that would be found in the specific solder pot therefore

we recommend labeling it as you would dross

Q. Is the spent MS2 considered hazardous?

A. As noted above, the spent MS2 contains oxides of the metals in your solder alloy therefore,

for example, spent MS2 that has been used to eliminate dross in a leaded alloy will contain lead

oxides and should be treated accordingly.

Q. How is MS2 different from the powders and oils that have been used in the past?

A. MS2 is a process chemical that not only inhibits dross formation but actually reduces dross

back to its native metals as it forms. There is no similarity of chemistry between the older materials

and the new technology MS2.

Q. MS2 is not a low priced material, how can I calculate my savings when using it?

A. A simple calculation is to determine how much 100 Lbs (45 Kg) of your solder costs as that

is how much dross a liter of MS2 reduces back into useable metal. Deduct the cost of that much

solder from your cost of one liter of MS2 and you will have a gross savings number. This of

course does not take into consideration the significant savings eliminating dross related rework

and reducing maintenance as well as increasing throughput will save. P. KAY metal has a savings

calculator available for use on the Companies web site that you can use for a more precise

calculation.

Q. What is the shelf life of MS2?

A. The shelf life is in excess of two years.

Q. Are there storage temperature limits while storing MS2?

A. The material should not be allowed to reach temperatures below 35 degrees F as some components

may separate. There is no practical upper limit to the material within all normally accepted

storage conditions. The material is stable at high temperatures.

(Continued from page 2)

(Continued on page 4)

Q. Why is MS2 200LF so much more expensive and why does it not contain lead?

A. The original formulation was optimized for lead free alloys. It was thought that with lead

free solders being so expensive that MS2 would find the most market acceptance in that area.

We soon found out that those using leaded solder had a great deal of interest in MS2 also. The

price of the MS2 200 LF (for lead free) was to high for economical use with cheaper leaded alloys

therefore a less pure, lower cost version, one that did not have to be optimized for lead free

RoHS compliant alloys was developed and offered to the market. MS2 200LF does not

contain lead because it is purified and optimized differently than the 100Pb which will

pick up lead in a cheaper quicker puri f i c a t i o n p r o c e s s .

Q. I see that there is a carbonized ring visible on my solder pot after using MS2. Is this normal

or harmful?

A. This is normal. Dross is not a clean byproduct. MS2 is far less messy than dross but it can

leave some residues which are easily reduced during normal maintenance. The carbon ring or

material that you see has no long term effects to your solder pot or process.

Q. what happens if we completely turn off our pots at the end of the day or for the weekend?

A. Letting the solder cool with the MS2 in place is not a problem unless the metal cools to the

solid state. When cooled to the point of being solid the metal can shrink away from the edges

allowing MS2 to seep in between the metal and the walls of the solder pot. While this will not

harm the pot the trapped MS2 will temporally give some smoke while the pot is re heating. If

the pot is allowed to cool to solid we recommend using a P. KAY metal supplied retainer ring

or simply remove the MS2 until the pot heated to near operating temperature once again.

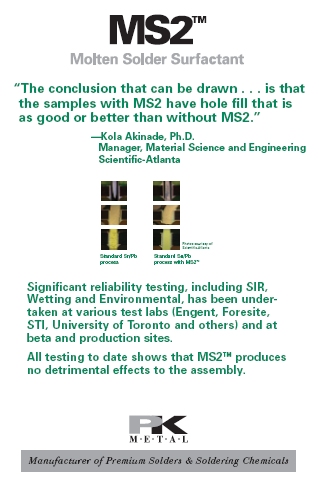

CLICK PHOTOS for PDF Poster

Lead-free solder bath without MS2® molten

solder surfactant, showing typical dross buildup

Lead-free solder bath with MS2® molten solder

surfactant, showing no dross—only shiny solder

|